Development

We work alongside your engineers with the objective of developing a part, tool and moulding process that is right first time.

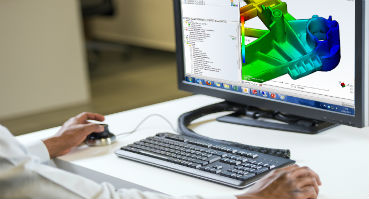

3D CAD and Moldflow

3D CAD and Moldflow

With our experience in the design of parts for injection moulding along with the latest 3D CAD and Moldflow software, we work in partnership with your engineers and advise on optimising your part design.

With Moldflow we can test design iterations, try different materials, and address potential quality issues early in development. If required, we can commission prototypes to further validate designs.

Tooling

Tooling

Working in partnership with established UK and Far East toolmakers, we offer a fully managed toolmaking service. We use a comprehensive AQP process to thoroughly understand your requirements before cutting metal.

Involving the customer and toolmaker, we advise on materials selection, tooling specification, and quality and validation requirements. The AQP forms the basis of all manufacturing and quality documentation and is used for all new and transfer tooling projects.

Validation

Validation

All tools are validated using process capability studies that ensure our moulding process is repeatable and component quality is consistent.

We also supply samples for your approval along with quality documentation such as ISIR, dimensional reports, gauge studies and PPAPs as per your requirements.

Moulding Quality

Moulding Quality

Accredited to ISO 9001, quality forms an integral part of all our processes. Using structured tools such as AQP and FMEA we create a rigorous and data driven quality regime that is bespoke to each part and includes the use of first off, in process and last off audits.

We have strict materials and documentation controls and provide full materials and moulding traceability for 10 years. In addition we use fully trained quality personnel along with a range of measuring and inspection equipment.

Strengthen Your Supply Chain +

Improve Your NPD +

Achieve Consistent Quality +